SDM Smelting (M) Sdn. Bhd.

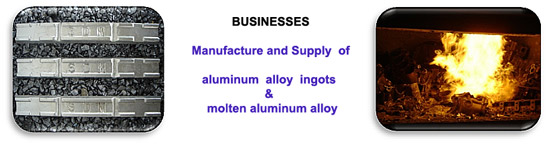

SDM Smelting (M) Sdn. Bhd. is a Malaysia Aluminum alloy ingot manufacturer, which was established in 2004 as a private limited company.

SDM Smelting offers a wide range of Aluminum alloy ingots for die casting applications meeting various international and customer's specialty standards.

SDM Smelting combined with SDM Group's strength in Aluminum business - worldwide networking, knowledge, technologies and expertise, enable us to supply a wide range of highly quality ingots to a number of international leading die casting companies.

SDM ingots are used to make high precision and stringent requirements casting products by key industrial sectors, including the automotive, electrical & electronics, oil & gas, information & telecommunication industries.

Company Data

Land area is 20,500 m2

Build up area is 3,500 m2

Equity structure :

20% Mr. Tan Boon Hai

20 % Mr. Tan Boon Chooi

20% Mr. Tan Boon Hoe

20% Mr. Tan Boon Hong

20% Ms . Ng Lee Lee

Authorized capital : RM5,000,000

Organization Chart

Production Capacity

SDM has one production line consists of melting furnace, alloying furnace and continuous casting system. Presently, SDM is capable to manufacture 600 tons/month of Aluminum ingots. We are planning to increase the capacity to 1600 tons/month by mid 2011 where additional of one larger production line will be installed in SDM new plant located at Meru Industrial Park.

We can produce specialty standards to meet customer's own composition targets in small batch size of 1 ton. SDM also works with international well known die casting companies in designing & supplying specialty specification of chemical composition in development of prototype products, if suitable standards do not exist.

Quality Policy

SDM Smelting (M) Sdn. Bhd. 's goal is to be the most preferred supplier of quality Aluminum alloy ingots & molten Aluminum alloy. The quality policy shall be strictly adhered and committed to..

S atisfying the very needs of local & international Aluminum casting customers

D eliver the products on-time and in-form to our customers

M aintain the best in quality management and practices, and continually improve the effectiveness of our QMS

ISO 9001 : 2008, re-certification on 27 May 2010 by DQS Certification Body |

SDM, an ISO9001 certified company is committed and always strive to maximize customer's satisfaction level at every optimized cost. We import only high grade Aluminum tense of mainly Japanese made engine and automotive scraps from international sources which either directly or in-directly related to the members of SDM Group. We are physically presence at the purchasing sources to inspect the scraps before acceptance, hence ensure the quality of input scrap Aluminum. Once the input materials arrive SDM plant, stringent inspections are conducted from weighing, segregation and pre-smelting activities, before the acceptance for melting process. Melting, alloying and casting processes are not only science & technology but also an art which required skilled & experienced staff members to perform the job. To further enhance the quality assurance, modern analyzing equipment are used to test on chemical composition of each melt batch and porosity check of gas content. Grain size, physical strength and dross content are determined at defined intervals. |

Meeting minimum specification on composition requirements

| Element | ADC12 Standard | SDM ADC12 | Minimum Std ADC12 |

| Cu | 1.5 % - 3.5% | 2.2% - 2.7% | 1.5 % - 1.7% |

| Mg | Less than 0.3% | Less than 0.26% | 0.28 % - 0.30% |

| Fe | Less than 0.9% | Less than 0.80% | 0.85% |

| Zn | Less than 1.0% | Less than 0.85% | 0.95% |

| Si | 9.5% - 12.0% | Customer's std | 9.6% when Si price is higher than Al; 11%when Si price is lower than Al |

Ingots meeting minimum specifications have high probability of non-compliance if instrument & sampling errors are take into consideration.

SDM ingots are not only meeting the requirements of composition specification but are controlled well above the minimum requirement of specification.

Cost Competitiveness

Aluminum ingot is an international priced and traded commodity. Ingot trading in physical market is guided by the prices of London Metal Exchange, LME. This is also applied to the trading of Aluminum scrap in the world market. However, due to local competitiveness and demand, the scrap prices are slightly varied in different locations for any given particular time period.

In response to increasingly customer needs in price competitiveness of ingots, we aim to source the lowest price possible of the input scrap Aluminum. To that end, we are gathering and concentrating the capabilities of SDM Group member companies of their worldwide scrap purchasing networking and warehouses, to only purchase the Aluminum scrap at the location where the price is the lowest, at the time of purchase.

Apart from sourcing outside the Group, SDM smelting has regular supply of scrap Aluminum internally. Presently, more than 50% of Aluminum scraps are supplied by SDM Group's End of Live Vehicle (ELV) Business Unit where we generate Aluminum tense from ELV recycling activities.

Product Specifications