SANDOMET Industries Sdn. Bhd.

SANDOMET was founded in 2000 and is now one of the largest and fastest growing worldwide recyclers of spent automotive catalytic converters. Today, Sandomet is the largest lot consolidator and dry processor of spent automotive catalytic converters in Southeast Asia. In Asia, Sandomet has a significant market share in all the countries and owns a several spent automotive cats decanning & sampling plants and representative collecting warehouses.

Sandomet is also one of the active traders of platinum group metals.

Dry Processes :

-

1) Removing the metal casing of spent automotive catalytic converters (decanning)

2) Crushing and sampling of automotive catalyst

3) Analysis of platinum, palladium & rhodium contents

In addition to the main activities in the recycling of spent automotive catalyst and platinum group metals trading, Sandomet is also playing the role of holding company for managing its subsidiaries which are involved in smelting and die casting of Aluminum alloy products, trading and warehousing of copper & stainless steel scraps, and recycling of end of live vehicles.

Company Information

Quality Policy

Sandomet Industries Sdn. Bhd. 's goal is to be the most preferred recycler of spent automotive and industrial catalysts. The quality policy shall be strictly adhered & committed to:

S atisfying the very needs of local & international suppliers of spent catalysts

D eliver the recycling services on-time and in-form to our suppliers

M aintain the best in quality management and practices, and continually improve the effectiveness of our QMS

What is a catalytic converter?

|

Air pollution from millions of cars on the road could had been a disaster if not because of the invention of catalytic converters. Most of countries have enacted laws & regulations to restrict the amount of air pollution that cars can emit. In order to comply with these laws & regulations, car makers have made improvement to the engines, fuel system as well as invention of catalytic converter which treats the exhaust gases before leaving the tail of exhaust pipe. Perfect combustion of air & fuel in car engine emit gases ; Nitrogen gas (N2) ,carbon dioxide (CO2) and water vapor (H2O). However, the combustion process is never perfect and harmful emission of gases : carbon monoxide (CO), hydrocarbons or volatile organic compounds (VOCs) and nitrogen oxides (NO and NO2 or NOx). The control of these three harmful emissions are the main aspects of laws & regulations. Catalytic converters are invented to meet the requirements of these laws & regulations in reducing the emission of these three gases (CO, VOCs and NOx) |

Today, most of catalytic converters have two functions: Reduction catalyst process and Oxidation catalyst process. The reduction catalyst uses rhodium to convert NOx to nitrogen and oxygen. Oxidation catalyst uses platinum and palladium to convert hydrocarbons to CO2, H2O and O2, and carbon monoxide to CO2.

Process Flow

| Market & Unit Price Analysis | The purchase price of each cat is based on its content of Pt, Pd & Rh and the market prices of these metals. Due to the complexity of this business, an online monitoring system (Sandomet Process System) has been established to accomplish this task. |

| Removing of spent catalytic converter from vehicle | This process is carried out by wrecking yard operators who are dismantling the scrap vehicles or vehicle repair shop operators who are replacing damaged catalytic converters. |

| Collection & lot consolidation of spent catalytic converters | Spent catalytic converter (cat) collectors are going around the wrecking yards and vehicle repair workshop to collect spent cats. Quantity of spent cats need to be in economic size before delivery to decanning plant |

| Segregation & grading | The cats are graded and grouped according to their values which relate to pgms content of each cat. |

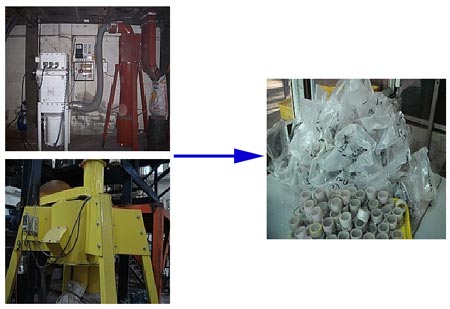

| De-canning | Remove the cat casing by hydraulic shearing machine. The honeycomb substrates are broken & dropped into collecting container |

| Crushing | Broken honeycomb substrates or catalysts are further crushed into fine particles / powders |

| Sampling | The powders are process thru fractional sampling machine where small quantity of powders are sampled out . Theses samples are divided into 4 sub-samples. (customer, analysis, store x 2) |

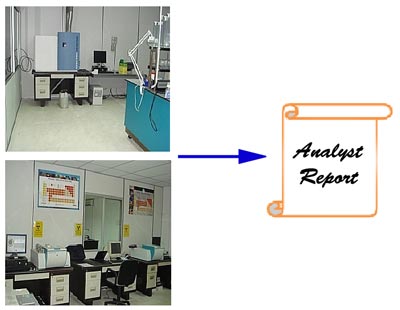

| Analysis | Samples are analyzed for moisture & Pt, Pd, Rh contents |

| Packing | The bulk catalysts are packaged and shipped to smelter for next process |

| Smelting | This process is to extract Pt, Pd and Rh from bulk catalysts |

| Refining | The final process of metals separation and refining into commodity grade form of Pt, Pd and Rh |

| Delivery of precious metals | The commodity grade of pgms are delivered to Sandomet's metal account or directly to Sandomet's customers premises |

| Trading of precious metals | Sandomet trade Pt, Pd and Rh actively in China markets |

Photos Gallery